MicroU™ - QuickStart Guide

MicroU™ - QuickStart Guide |

|

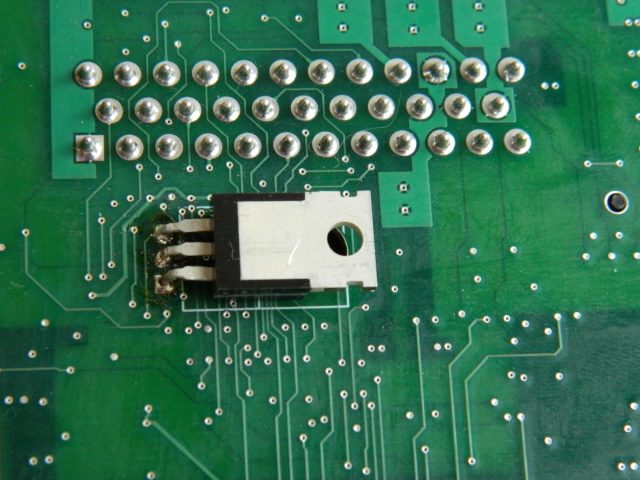

The TIP125 Darlington transistor on the 1AMP circuit for the pressure control solenoid (aka. "force motor") needs to be installed by the user on the beta microTCU™ units. The TIP125 mounts on the bottom side of the board, and a heat sink can be placed under it (against the case).

Testing has shown that the TIP125 does not require a heat sink when driving an early version of the 4L60e's pressure control solenoid (aka. "force motor") which has a DC resistance of about 4 Ohms. Further testing shows that the TIP125 does not require a heat sink when driving a DC resistance of more than 3 Ohms at 60% PWM (the upper limit of PWM% per GM specifications for the 4L60e pressure control solenoid). In these cases, the TIP125 can be installed in the case without a heat sink. However, for lower resistances or higher PWM percentages, the heat sink is required. There my be cases in which higher resistances require a heat sink, depending on things like the solenoid's inductance, but this will be determined in beta testing. If you are not sure if you need a heat sink, it doe not hurt to install one in any application (and this may provide the ultimate reliability).

There is a hole directly above the TIP125 mounting location, but the hole isn't for mounting the TIP125, it is for passing a screwdriver through to screw the TIP125 to a heat sink where required.

The heat sink is made from a sheet of aluminum mounted on the outside of the case. It is held in place by the TIP125 mounting screw. It should be 1.5mm (0.060") to 2.5mm (0.100") thick, and at least 6 cm2 (1 square inch) in area (larger is better).

The screw is the primary method of conducting heat from the TIP125 to the heat sink, make sure it is snug and cannot come loose (a dab of paint on the nut after tightening will work).

Unfortunately, the cases for the beta microTCU™ units are from a MicroSquirt™ controller, as we don't have specific cases for the microTCU™ controller yet. The result is that the heat sink must be externally mounted, which isn't ideal (because the heat sink is electrically 'hot').

The tab of the TIP125 is electrically connected to the collector. That means is is connected to the PC solenoid. As a result, the heat sink MUST NOT BE ALLOWED TO TOUCH GROUND when it is mounted, as this will provide maximum current flow through the pressure control solenoid at all times (giving minimal line pressure that might damage the transmission, and maximal current that might damage your microTCU™ controller). If necessary, you can insulate the heat sink electrically (with dielectric tape, for example), though this will affect its ability to conduct heat away from the TIP125, of course.

Alternatively, for the ultimate cooling and reliability, the case could be cut away under the TI125, and the TIP125 mounted directly to the aluminum heat sink. You should insulate the 'electrically hot' tab of the TIP125 from the heat sink by using a mica insulator (ex. Keystone 4724, part number 534-4724 at Mouser), in which case the heat sink does not have to be isolated from ground. You must also insulate the mounting bolt from the tab using dielectric washers, often supplied in a kit with the mica insulator itself.

If you choose to use a mica insulator rather than isolate the heat sink, then you should check that you have very high resistance (more than ~1 million Ω) between the tab of the TI125 and the heat sink when it is install. Do not power the controller up until you have very high resistance, or you could damage the board, power supply, and/or other components.

Note that the PCB sits about 4mm (0.16") above the bottom of the case. A typical TIP125 is about 4mm thick, and the TIP125 will just fit into the case without a heatsink.

Enjoy driving your microTCU™ controller equipped vehicle! If you have any questions or problems, you can: